Pulleys can be of various types and are often used on the basis of what the actual need is anywhere. The range of applications where these different types of pulley systems are used is big. From drivetrains to smaller parts in mechanisms, they tend to be everywhere.

In this article, we are going to discuss the various types of pulley systems that are present. We will also look at what these pulleys are particularly used for. So, let’s dive into it.

Pulley:

A pulley is essentially a small wheel with a grooved rim for gripping a rope or similar object. This rope can be used to elevate or lower anything by applying a simple pull force at one end.

The combinations and placement of many such pulleys can give birth to different mechanisms and systems that can be more beneficial than a single pulley.

Given below are some of the types of pulleys and their combined systems listed.

Types of Pulleys:

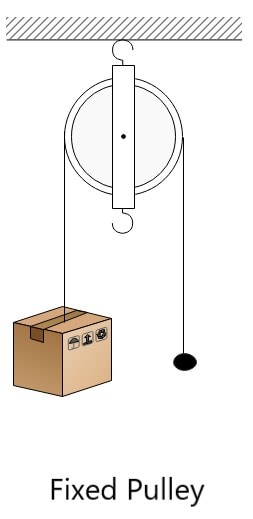

1. Fixed Pulley:

As the name suggests a fixed pulley is a pulley that is permanently attached to a place and cannot move. The only degree of freedom that it is equipped with is rotation. It changes the direction of the applied force. This type of pulley offers no mechanical advantage as the same amount of force is required

We can see such fixed pulleys used for drawing water out of wells. The pulleys remain at one place intact. It acts as a support for the person pulling the rope to draw water out from the well.

A flag post pulley is another example of a fixed pulley because it is fixed at a place and helps in flag hoisting.

Gym equipment also consists of fixed pulleys. These pulleys are placed according to the nature of exercise done on the equipment.

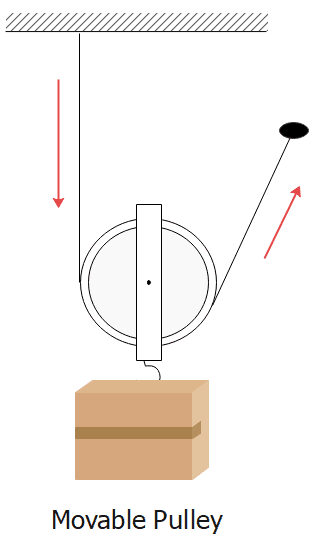

2. Movable pulley:

A movable pulley is not attached to a particular place and is thus free to move along the rope. Here wheel supports the load and the effort is in the same direction as that of the movement. This arrangement reduces the forces needed to move an object.

These pulleys mostly move vertically with help of their own weight. They can move with the help of tension in the rope. This tension is built up by the whole mechanism where other types of pulleys are also present.

A crane is an application where movable pulleys are used. The hook in the front of the crane is essentially a movable pulley. It can be lowered to hook an object to it and then can move vertically upwards to lift the object from the ground.

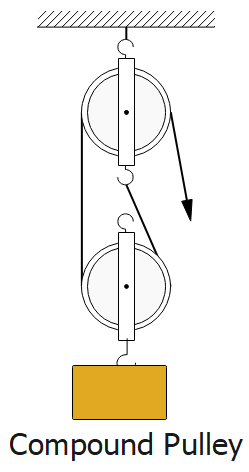

3. Compound pulley:

The mechanism in which the combination of a fixed and a movable pulley is used is known as a compound pulley. The compound pulley can be a combination of many such fixed and movable pulleys.

This gives a mechanical advantage by reducing the force applied at one end to lift a heavy object.

A crane uses such a mechanism where it has both types of pulleys (simple and movable) to help it lift heavier objects.

4. Cone Pulley:

Cone pulleys are also known as stepped pulleys. These pulleys are used where speeds are to be managed for a particular operation.

Three-quarter-ten, CC BY-SA 3.0, via Wikimedia CommonsIt can be a lathe machine or a CVT (Continuously Variable Transmission) that is used nowadays in cars. In this, there is a set of cone pulleys that are connected through a belt to transmit power. One of the pulleys is connected to the engine to receive power from it and which transmits it further.

The conical section distance between pulleys is managed to meet the current needs of the car speed while driving. They also help while working in conjunction with the engine to maintain the torque provided.

5. Block and tackle pulley:

This pulley system is like the compound pulley system where a fixed pulley and a movable pulley work together in a mechanism but an extra fixed pulley is attached to the mechanism to help it with lifting heavier weights.

6. Conveyor Belt Pulley:

Conveyor belts are used in many places such as manufacturing plants, construction sites, various mines, etc. You may encounter these belts at such mines where the main material which is transferred through it is sand, heavy bags of cement or any other bulky material.

This conveyor belt is nothing but a motor attached to a big pulley having a width equal to the width of the belt. The friction between the pulley surface and the belt’s surface makes the whole mechanism move through the tension created in the belt.

7. Jockey Pulley:

When we use pulleys with belts to transmit power from one pulley to another, the belts get loose with time and this can lead to loss of energy due to slipping of these belts.

To counter this fatigue phenomenon, jockey pulley systems are used where various pulleys are used other than the main input and output pulleys known as idler pulleys to keep the belt/rope in tension and no major energy losses occur.

8. Swivel Eye Pulley:

A swivel eye pulley is basically a fixed pulley with an extra degree of freedom of rotation around another axis.

It means that with the default rotation of the pulley which is used to lift and lower the attached objects it can also rotate around the suspended rope as the other axis.

Therefore it can be used in applications where heavier objects are to be placed by lifting and rotating at a certain angle to complete the fit or the task the heavier object is assigned with.

9. Complex Pulley:

A complex pulley system is more complicated than a simple or compound pulley system and comprises many pulleys. It also has pulley(s) which move in the opposite direction of the loading of the anchor.

Conclusion:

Pulleys have great importance in various machines. The various mechanisms that can be achieved to solve certain problems in the industry are the most important thing about pulleys.

The systems that we discussed above are a few of the many systems that are currently used in today’s world.

But still, the potential of pulley systems is huge and we are certainly going to see more of such innovative systems in the future.

Also, visit our article on Examples of Pulleys